Better together - introduce continous improvement

with Polaris and evolve your production

Change can be driven only by two motivations: Pain or Gain. Put into simple behavior patterns; Humans will change because they believe that pain from the threatening negative consequences that persisting in the current state would entail, Gain is chased by people who follow an enticement and hope for improvement. For any change the key to success is understanding how to manage the change using these principles.

When implementing CIP, this is not a one-shot approach, but a permanent need to keep up the motivation to continuously challenge the status quo and engage on permanent change.

From several years of CIP tool and way of working change implementation we see a repeating pattern of failures trying to implement sophisticated Production Systems which never become a self-running system and finally disappear. We identified the following reasons for the failure:

1. Too much tool focus.

2. No understanding for “real” human motivation drivers.

3. Missing CIP Operating Model including CIP driver Organization and Governance Model empowering the motivation pattern.

Due to this we have witnessed a lot of excellent lean experts leave frustrated the profession as well as companies fail implementing any kind of lean excellence, since the initiative was designed as a toothless lion.

If you want to avoid this keep on reading!

Toyota, being the most successful und one of the most profitable car makers in the world, has created and established the CIP culture as its operating excellence foundation. Looking closely, it reveals the this is not a technical principle but a basic mindset empowering anybody to permanently think and act on the next improvement. Over the last 60 years it has become part of their corporate DNA.

Many other companies around the world have copied this approach but only a few have succeeded in getting to a DNA level. Where most failures are not caused by having made mistakes in choosing the wrong tools or methods but furthermore did not consider the mechanisms of Organization and Governance to drive the CIP mind-set and motivation.

Don’t get it wrong, tools and methods are an important brick, but even more important is how they are embedded to empower the acting and driving functions with the right drive and success targets.

Therefore, before starting by selecting and specifying tools and methods the following questions should be envisioned:

5. How is ensured that the company performance and excellence targets can be enforced on the operation without getting dffddcaught up in hierarchal conflicts of interest

6. How can a wide buy in on the operational level be ensured

7. How will the CIP success be measured and what is a success and what not

8. How will the result be being integrated into the financial budget model

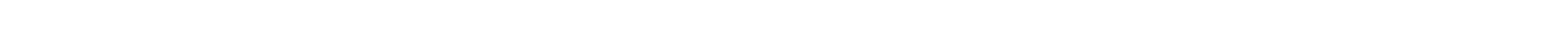

The following bricks of the CIP Operations and Governance Modell should answer these questions:

Continous improvement operating mode

The big picture - capture vision and ambition

As key stakeholders of the entity you define your vision and ambition, which guides the continuous improvement approach. This is the start of your journey to get to your best version. We support you with our many years of knowledge so that you can set an efficient focus

Together we will define the first steps:

- What do you want to achieve?

- Can you measure your goals?

Take a closer look and identify improvement drivers

Our experience shows that this is the first thing you should set your focus on. Our consultants will help you to get an understanding of what the main cost and improvement drivers in your company are. Together, we will select the most important drivers which should be addressed first.

We will analyze your production with Polaris VSM:

- What drives the pain and inefficiency in the company

in relation to workload, qualitiy or leas time? - Where do you have to focus on in order to look for

improvement?